Lincoln Aviator 2020-2025 Service Manual / Powertrain / Engine / Engine - 3.0L EcoBoost / Removal and Installation - Camshaft Roller Follower

Lincoln Aviator: Engine - 3.0L EcoBoost / Removal and Installation - Camshaft Roller Follower

Special Tool(s) / General Equipment

.jpg) |

303-1633 Remover, Roller Rocker Follower TKIT-2014D-ROW3 TKIT-2014D-FL_ROW |

Removal

NOTICE: During engine repair procedures, cleanliness is extremely important. Any foreign material, including any material created while cleaning gasket surfaces, that enters the oil passages, coolant passages or the oil pan, can cause engine failure.

-

Remove the LH and/or RH valve covers.

Refer to: Valve Cover LH (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

Refer to: Valve Cover RH (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

-

Rotate the crankshaft pulley bolt clockwise to position

the camshaft lobe upward for the camshaft roller follower to be removed.

.jpg) |

-

- Install Special Service Tool: 303-1633 Remover, Roller Rocker Follower.

-

Turn the knob on the special tool clockwise to depress the valve and spring.

-

Unclip the camshaft roller follower from the

hydraulic lash adjuster and remove the camshaft roller follower.

.jpg) |

Installation

-

NOTE: Component(s) must be lubricated with clean engine oil.

-

Lubricate the camshaft roller follower with clean engine oil.

-

Position the camshaft roller follower and engage the clip onto the hydraulic lash adjuster.

-

Turn the knob on the special tool counterclockwise to raise the valve and spring.

-

Remove Special Service Tool: 303-1633 Remover, Roller Rocker Follower.

-

Lubricate the camshaft roller follower with clean engine oil.

.jpg) |

-

Install the LH and/or RH valve covers.

Refer to: Valve Cover LH (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

Refer to: Valve Cover RH (303-01A Engine - 3.0L EcoBoost, Removal and Installation).

Removal and Installation - Camshaft RH

Removal and Installation - Camshaft RH

Special Tool(s) /

General Equipment

303-1633Remover, Roller Rocker FollowerTKIT-2014D-ROW3TKIT-2014D-FL_ROW

Materials

Name

Specification

Flange SealantCU7Z-19B508-A

WSS-M2G348-A11

Removal

NOTICE:

During engine repair procedures, cleanliness is extremely

important...

Removal and Installation - Crankshaft Front Seal

Removal and Installation - Crankshaft Front Seal

Special Tool(s) /

General Equipment

303-1531Installer, Front Crank Seal and Damper

303-335

(T88T-6701-A)

Installer, Front Cover Oil SealTKIT-1988-FLMTKIT-1988-F

303-409

(T92C-6700-CH)

Remover, Crankshaft SealTKIT-1992-FH/FMH/FLMHTKIT-1993-LMH/MH

Removal

Remove the crankshaft pulley...

Other information:

Lincoln Aviator 2020-2025 Service Manual: Description and Operation - Transmission Fluid Auxiliary Pump

Item Description 1 Transmission fluid auxiliary pump 2 Transmission fluid auxiliary pump tube 3 Transmission fluid auxiliary pump tube seal 4 Transmission fluid auxiliary pump tube O-ring 5 Transmission fluid auxiliary pump fluid inlet 10-speed transmissions with the auto-start stop feature are equipped with a transmission fluid auxiliary pump...

Lincoln Aviator 2020-2025 Owners Manual: Windshield Washers

Pull the lever toward you to operate the windshield washers. When you release the lever, the wipers operate for a short time. When activated, a courtesy wipe occurs a short time after the wipers stop to clear any remaining washer fluid. Note: You can switch courtesy wipe on or off in the touchscreen...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Anti-Theft Alarm

- Body and Paint

- Locking and Unlocking

- New on site

- Most important about car

Fastening the Seatbelts

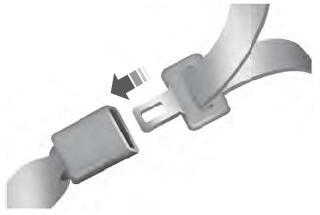

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2025 www.liaviator2.com