Lincoln Aviator 2020-2025 Service Manual / Powertrain / Automatic Transmission / Automatic Transmission - 10-Speed Automatic Transmission – 10R60 / Diagnosis and Testing - A Clutch

Lincoln Aviator: Automatic Transmission - 10-Speed Automatic Transmission – 10R60 / Diagnosis and Testing - A Clutch

Symptom Chart

A Clutch

For A clutch operation,

REFER to: A Clutch (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Description and Operation).

A Clutch

| Condition | Possible Sources | Action |

| A clutch does not apply | SSA mechanically stuck OFF |

INSTALL a new solenoid. REFER to: Shift Solenoids (SS) (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

| A clutch control valve stuck OFF |

DISASSEMBLE, CLEAN and INSPECT the A clutch

control valve. If the bore or valve is damaged, INSTALL a new main

control valve body. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

| A clutch latch valve stuck OFF |

DISASSEMBLE, CLEAN and INSPECT the A clutch

latch valve. If the bore or valve is damaged, INSTALL a new main control

valve body. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

| A clutch hydraulic circuits blocked/leaking |

DISASSEMBLE and INSPECT the main control

valve body and separator plate passages for debris, blockage and leaks.

CLEAN as necessary. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

|

CARRY OUT the air pressure test on the A clutch. REFER to: Special Testing Procedures (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing). If a leak is detected, INSPECT the front support assembly and A clutch piston seals for leaks. INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

||

| Front support assembly, ring gear no. 1 |

DISASSEMBLE and INSPECT the front support

assembly hydraulic passages for debris, blockage or leaks. INSPECT the

front support assembly and ring gear no. 1 for wear and damage. CLEAN or

INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch piston seals |

DISASSEMBLE and INSPECT the A clutch piston

seals for wear and damage. INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch friction plates |

DISASSEMBLE and INSPECT the A clutch

friction and steel plates for wear and damage. INSTALL new components as

necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch always applied | SSA mechanically stuck ON |

INSTALL a new solenoid. REFER to: Shift Solenoids (SS) (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

| A clutch control valve stuck ON |

DISASSEMBLE, CLEAN and INSPECT the A clutch

control valve. If the bore or valve is damaged, INSTALL a new main

control valve body. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

| A clutch latch valve stuck ON |

DISASSEMBLE, CLEAN and INSPECT the A clutch

latch valve. If the bore or valve is damaged, INSTALL a new main control

valve body. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

| A clutch hydraulic circuit cross leaks |

DISASSEMBLE and INSPECT the main control

valve body and separator plate passages for cracks, warping and damage.

If damage is found, INSTALL a new main control valve body. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

| Front support assembly, ring gear no. 1 |

DISASSEMBLE and INSPECT the front support

assembly hydraulic passages for debris, blockage and leaks. Inspect the

front support assembly and ring gear no. 4 for wear and damage. CLEAN or

INSTALL new components necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch piston return spring |

DISASSEMBLE and INSPECT the A clutch piston

return spring for damage. INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch friction plates |

DISASSEMBLE and INSPECT the A clutch

friction and steel plates for wear and damage. INSTALL new components as

necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch delayed/soft/slipping apply | Incorrect transmission strategy programmed into PCM/ TCM. |

CARRY OUT the Transmission Strategy Download and the Adaptive Learning Drive Cycle. REFER to: Transmission Strategy Download (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, General Procedures). REFER to: Adaptive Learning Drive Cycle (307-01B Automatic Transmission - 10-Speed Automatic Transmission – 10R80 MHT, General Procedures). |

| Low line pressure |

CARRY OUT the line pressure test. If line

pressure is low, REFER to the Line Pressure Diagnosis Chart. REFER to: Special Testing Procedures (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing). |

|

| SSA mechanically sticking |

|

|

| A clutch control valve sticking |

|

|

| A clutch latch valve sticking |

|

|

| A clutch hydraulic circuits blocked/leaking |

DISASSEMBLE and INSPECT the main control

valve body and separator plate passages for debris, blockage and leaks.

CLEAN as necessary. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

|

CARRY OUT the air pressure test on the A clutch. REFER to: Special Testing Procedures (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing). If a leak is detected, INSPECT the front support assembly and A clutch piston seals for leaks. INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

||

| A clutch piston seals |

DISASSEMBLE and INSPECT the A clutch piston

seals for wear and damage. INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch friction plates |

DISASSEMBLE and INSPECT the A clutch

friction and steel plates for wear and damage. INSTALL new components as

necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch harsh apply | Incorrect transmission strategy programmed into PCM/ TCM. |

CARRY OUT the Transmission Strategy Download and the Adaptive Learning Drive Cycle., REFER to: Transmission Strategy Download (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, General Procedures). REFER to: Adaptive Learning Drive Cycle (307-01B Automatic Transmission - 10-Speed Automatic Transmission – 10R80 MHT, General Procedures). |

| High line pressure |

CARRY OUT the line pressure test. If line

pressure is high, REFER to the Line Pressure Diagnosis Chart. REFER to: Special Testing Procedures (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Diagnosis and Testing). |

|

| SSA mechanically sticking |

|

|

| A clutch control valve sticking |

|

|

| A clutch latch valve sticking |

|

|

| A clutch hydraulic circuit blocked/leaking |

DISASSEMBLE and INSPECT the main control

valve body and separator plate passages for debris, blockage and leaks.

CLEAN as necessary. REFER to: Main Control Valve Body (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Removal and Installation). |

|

| A clutch piston return spring |

DISASSEMBLE and INSPECT the A clutch piston

return spring for damage. INSTALL new components as necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

|

| A clutch friction plates |

DISASSEMBLE and INSPECT the A clutch

friction and steel plates for wear and damage. INSTALL new components as

necessary. REFER to: Transmission (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Overhaul). |

Diagnosis and Testing - Special Testing Procedures

Diagnosis and Testing - Special Testing Procedures

Line Pressure Test

This test verifies the line pressure is within specification.

If available, refer to the Transmission Line Pressure Test general procedure to access the line pressure tap...

Diagnosis and Testing - B Clutch

Diagnosis and Testing - B Clutch

Symptom Chart

B Clutch

For B clutch operation, REFER to: B Clutch (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Description and Operation)...

Other information:

Lincoln Aviator 2020-2025 Service Manual: Removal and Installation - Rear Door Fixed Window Glass

Removal NOTE: The rear window fixed glass assembly is part of the rear door glass top run and cannot be serviced separately. Remove the rear door glass top run. Refer to: Rear Door Glass Top Run (501-11 Glass, Frames and Mechanisms, Removal and Installation)...

Lincoln Aviator 2020-2025 Service Manual: Specifications

Battery Specifications Base and Reserve without trailer tow vehicles Item Specification Voltage 12 Volts Cold Cranking Amps (CCA) measured at -18 C (-0.4 F) 800 Cold Cranking Amps (CCA) Battery amps rating 80 Ah Battery size H7 Battery type Absorbed Glass Mat (AGM) All other vehicles Item Specification Voltage 12 Volts Cold Cranking Amps (CCA) measured at -18 C (-0...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Configuring The Head Up Display

- USB Port and Power Point Locations

- Opening and Closing the Hood

- New on site

- Most important about car

Fastening the Seatbelts

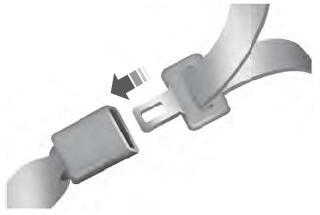

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

Copyright © 2025 www.liaviator2.com