Lincoln Aviator: Automatic Transmission - 10-Speed Automatic Transmission – 10R60 / Description and Operation - Transmission Description - System Operation and Component Description

System Diagram

.jpg)

| Item | Description |

|---|---|

| 1 | SSB |

| 2 | SSC |

| 3 | SSD |

| 4 | SSE |

| 5 | SSF |

| 6 | LPC |

| 7 | TSS |

| 8 | ISSB |

| 9 | Transmission |

| 10 | Transmission |

| 11 | TFT |

| 12 | TRS |

| 13 | SSA |

| 14 | PCM |

| 15 | TCC |

| 16 | OSS |

| 17 | ISSA |

| 18 | GSM |

| 19 | PBW |

Network Message Chart

| Broadcast Message | Originating Module | Message Purpose |

|---|---|---|

| Engine Speed | PCM | Directly affects shift scheduling, TCC control, line pressure and transmission diagnostics. Indirectly affects shift pressure control. |

| Engine torque estimate | PCM | Directly affects shift pressure control, TCC control and transmission diagnostics. Indirectly affects shift scheduling and TCC scheduling. |

| APP | PCM | Directly affects shift scheduling, TCC scheduling and transmission diagnostics. Indirectly affects TCC control and shift control. |

| Commanded engine torque | PCM | Directly affects shift scheduling, TCC scheduling and transmission diagnostics. Indirectly affects shift control. |

System Operation

The 10R60 transmission is a 10-speed, step ratio rear wheel drive transmission that is controlled by a PCM. The 10R60 has ten forward speeds, one reverse speed, four planetary gearsets, one mechanical One-Way Clutch or OWC, six friction clutches, an upper valve body, a lower valve body with eight solenoids, and PCM controlled electronics. The 10R60 utilizes six shift (A-F) solenoids that are linear force solenoids. Unlike previous shift solenoids they are mechanical in nature in that no transmission fluid passes through them. CIDASs use a armature/pin assembly that moves a control valve in the main control valve body to control and apply hydraulic fluid pressure. Each clutch (A-F) is controlled by a corresponding shift solenoid (A-F). These solenoids are directly proportional in that zero current equals zero pressure and maximum current equals maximum pressure. If the power circuit to the transmission solenoids fails open, then all solenoids are failed electrically OFF, none of the clutch packs are able to engage and there is no fail safe operation.

Upshift Gear Sequence

At times the 10-speed transmission may skip gears when the vehicle starts from a complete stop. This is normal and desired behavior.

At part pedal when acceleration is brisk, single step upshifts would result in very frequent shift events (very short time in gear). Double step upshifts results when a longer time is spent in gear.

However, at light pedal or road load, single step upshifts will occur. The small 10-speed gear steps allow the engine speed to drop to lower values than it would in the 6-speed transmission; providing for the best fuel economy. In contrast, when the 10-speed transmission is at heavy or max pedal, the small steps keep the engine closer to the horsepower peak for best performance.

Down shift Gear Sequence

At times the 10-speed transmission may skip gears when the vehicle downshifts to a complete stop. This is normal and desired behavior.

The same skip shift strategy that is used for the upshift may be applied during downshift.

Component Description

Hydraulic Circuits

Line Pressure Hydraulic Circuits

.jpg)

| Item | Description |

| 1 | Mechanical pump |

| 2 | Pump output |

| 3 | Main regulator valve |

| 4 | Pump output decreased |

| 5 | LPC solenoid |

| 6 | LPC pressure |

| 7 | Isolator valve |

| 8 | Anti-backflow valve |

| 9 | Transmission fluid auxiliary pump |

| 10 | Line pressure |

The PCM controls line pressure with the LPC solenoid. Varying pressure from the LPC solenoid affects shift feel while allowing sufficient pressure for clutch application.

When the engine is running, the pump supplies pressure to the main regulator valve through the pump output circuit. Pressure from the LPC solenoid through the LPC pressure circuit controls the position of the main regulator valve.

The main regulator valve varies pressure in the pump output circuit.

The transmission fluid auxiliary pump, an electronic pump in turned on before an engine stop event to maintain line pressure, allowing the transmission to stay engaged during the stop event. This allows quick response on the engine restart because the transmission is already in gear.

Lubrication Hydraulic Circuits

.jpg)

| Item | Description |

| 1 | Fluid from torque converter |

| 2 | Lube control valve |

| 3 | Lube fluid circuit |

| 4 | Elevated exhaust pressure |

| 5 | Thermal bypass valve without active warm up |

| 6 | Bypass valve with active warm up |

| 7 | Fluid cooler |

A small amount of hot fluid from the torque converter is routed through a small orifice in the separator plate to the transmission fluid cooler or transmission fluid warmer/cooler. This fluid purges the cooler or warmer/cooler of air and keeps the cooler or warmer/cooler full of fluid when the vehicle is running.

On vehicles without active warm up, most of the hot fluid from the torque converter is routed to the thermal bypass valve. When TFT is below a specified temperature, the thermal bypass valve directs the fluid to the lube circuit. When TFT is above a specified temperature, the thermal bypass valve directs fluid to the transmission fluid cooler. Cold fluid from the transmission fluid cooler is routed to the lube circuit.

On vehicles with active warm up, most of the hot fluid from the torque converter is routed through the bypass valve to the transmission fluid warmer/cooler. Cold fluid from the transmission fluid cooler is routed to the lube circuit.

Fluid in the lube circuit enters the input shaft through the front support assembly and flows through passages in the input shaft and output shaft to provide lubrication for the transmission.

Powerflows

1st Gear

.jpg)

| Item | Description |

| 1 | E clutch |

| 2 | Input shaft |

| 3 | Shell and sun gear No. 4 |

| 4 | A clutch |

| 5 | One-Way Clutch (OWC) |

| 6 | Ring gear No. 4 |

| 7 | Output shaft and planetary carrier No. 4 |

| 8 | D clutch |

The E clutch is applied allowing torque to be transferred from the input shaft to the shell and sun gear No. 4. The A clutch and the One-Way Clutch (OWC) are both applied to hold the ring gear No. 4 stationary on acceleration. The shell and sun gear No. 4 drives the pinions of the output shaft and planetary carrier No. 4 in a 4.69 reduction gear ratio. The D clutch is applied to reduce frictional losses from a released clutch, but does not contribute to powerflow.

2nd Gear

.jpg)

| Item | Description |

| 1 | One-Way Clutch (OWC) |

| 2 | Sun gear No. 2 |

| 3 | Input shaft |

| 4 | Planetary carrier No. 2 |

| 5 | Ring gear No. 2 and sun gear No. 3 |

| 6 | C clutch |

| 7 | D clutch |

| 8 | Planetary carrier No. 3 |

| 9 | Ring gear No. 3 |

| 10 | Shell and sun gear No. 4 |

| 11 | A clutch |

| 12 | Ring gear No. 4 |

| 13 | Output shaft and planetary carrier No. 4 |

The One-Way Clutch (OWC) holds the sun gear No. 2 stationary on acceleration. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 and sun gear No. 3 to rotate at a 0.63 overdrive ratio. The C clutch and the D clutch are applied allowing torque to be transferred from the ring gear No. 2 to the planetary carrier No. 3 at a 0.63 overdrive gear ratio. The 2 inputs to the 3rd planetary gearset cause the ring gear No. 3 and the planetary carrier No. 3 to rotate at a 0.63 overdrive ratio. The A clutch and the One-Way Clutch (OWC) are both applied to hold the ring gear No. 4 stationary on acceleration. The shell and sun gear No. 4 drives the pinions of the output shaft and planetary carrier No. 4 in a 2.98 reduction gear ratio.

3rd Gear

.jpg)

| Item | Description |

| 1 | C clutch |

| 2 | D clutch |

| 3 | E clutch |

| 4 | Planetary gearset No. 2 |

| 5 | Planetary gearset No. 3 |

| 6 | Sun gear No. 1 |

| 7 | Shell and sun gear No. 4 |

| 8 | Input shaft |

| 9 | A clutch |

| 10 | Ring gear No. 1 |

| 11 | Ring gear No. 4 |

| 12 | Output shaft and planetary carrier No. 4 |

The C clutch, D clutch, and the E clutch are applied to provide multiple inputs at the same speed to the 2nd and 3rd planetary gearsets. These inputs effectively lock the 2nd and 3rd planetary gearsets and cause sun gear No. 1 and the shell and sun gear No. 4 to rotate at a 1:1 ratio with the input shaft. The A clutch is holding the ring gear No. 1 stationary causing the planetary carrier No. 1 and the ring gear No. 4 to rotate at a 3.11 reduction ratio. The 2 inputs to the 4th planetary gearset cause the output shaft and planetary carrier No. 4 to rotate at a 2.15 ratio.

4th Gear

.jpg)

| Item | Description |

| 1 | C clutch |

| 2 | D clutch |

| 3 | F clutch |

| 4 | Planetary gearset No. 3 |

| 5 | Planetary gearset No. 4 |

| 6 | Planetary carrier No. 1 |

| 7 | Ring gear No. 2 |

| 8 | A clutch |

| 9 | Ring gear No. 1 |

| 10 | Input shaft |

| 11 | Output shaft and planetary carrier No. 4 |

The C clutch, D clutch, and F clutch are applied effectively locking the 3rd and 4th planetary gearsets, the planetary carrier No. 1, and the ring gear No. 2 together. The A clutch is holding the ring gear No. 1. The 2 inputs to the planetary gearset No. 1 cause the sun gear No. 1 and the sun gear No. 2 to rotate at a 0.56 overdrive ratio. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 and the 4th planetary gearset to rotate at a 1.77 ratio.

5th Gear

.jpg)

| Item | Description |

| 1 | C clutch |

| 2 | F clutch |

| 3 | Planetary carrier No. 1 |

| 4 | Ring gear No. 2 |

| 5 | Ring gear No. 4 |

| 6 | A clutch |

| 7 | Ring gear No. 1 |

| 8 | Sun gear No. 1 |

| 9 | Sun gear No. 2 |

| 10 | E clutch |

| 11 | Shell and sun gear No. 4 |

| 12 | Input shaft |

| 13 | Output shaft and planetary carrier No. 4 |

The C clutch and F clutch are applied effectively locking the planetary carrier No. 1, the ring gear No. 2, and ring gear No. 4 together at a 1.77 ratio. The A clutch is holding the ring gear No. 1. The 2 inputs to the planetary gearset No. 1 cause the sun gear No. 1 and the sun gear No. 2 to rotate at a 0.56 overdrive ratio. The E clutch is applied to transfer torque to the sun gear No. 4. The 2 inputs to the 4th planetary gearset cause the output shaft and planetary carrier No. 4 to rotate at a 1.52 ratio.

6th Gear

.jpg)

| Item | Description |

| 1 | D clutch |

| 2 | F clutch |

| 3 | Planetary carrier No. 1 |

| 4 | Planetary carrier No. 3 |

| 5 | Ring gear No. 4 |

| 6 | A clutch |

| 7 | Ring gear No. 1 |

| 8 | Sun gear No. 1 |

| 9 | Sun gear No. 2 |

| 10 | Input shaft |

| 11 | Ring gear No. 2 and sun gear No. 3 |

| 12 | E clutch |

| 13 | Ring gear No. 3 |

| 14 | Shell and sun gear No. 4 |

| 15 | Output shaft and planetary carrier No. 4 |

The D clutch and F clutch are applied effectively locking the planetary carrier No. 1, the planetary carrier No. 3, and the ring gear No. 4 together. The A clutch is holding the ring gear No. 1. The 2 inputs to the planetary gearset No. 1 cause the sun gear No. 1 and the sun gear No. 2 to rotate at a 0.44 overdrive ratio. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 and sun gear No. 3 to rotate at a 3.58 ratio. The E clutch is applied to transfer torque from the input shaft to the ring gear No. 3 and the shell and sun gear No. 4. The 2 inputs to the 3rd planetary gearset cause the planetary carrier No. 3 and ring gear No. 4 to rotate at a 1.38 ratio. The 2 inputs to the 4th planetary gearset cause the output shaft and planetary carrier No. 4 to rotate at a 1.28 ratio.

7th Gear

.jpg)

| Item | Description |

| 1 | C clutch |

| 2 | D clutch |

| 3 | F clutch |

| 4 | E clutch |

| 5 | Input shaft |

| 6 | Output shaft and planetary carrier No. 4 |

The C clutch, D clutch, F clutch and the E clutch are applied to provide multiple inputs at the same speed to all four planetary gearsets. These inputs effectively lock all four planetary gearsets causing the output shaft and planetary carrier No. 4 to rotate at a 1:1 ratio with the input shaft.

8th Gear

.jpg)

| Item | Description |

| 1 | A clutch |

| 2 | One-Way Clutch (OWC) |

| 3 | Input shaft |

| 4 | Sun gear No. 2 |

| 5 | Ring gear No. 2 and sun gear No. 3 |

| 6 | D clutch |

| 7 | F clutch |

| 8 | Ring gear No. 4 |

| 9 | E clutch |

| 10 | Shell and sun gear No. 4 |

| 11 | Output shaft and planetary carrier No. 4 |

The B clutch is holding the sun gear No. 2 stationary. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 and sun gear No. 3 to rotate at a 0.63 overdrive ratio. The D clutch and F clutch are applied allowing torque to be transferred from the planetary No. 3 to the ring gear No. 4 at a 0.82 overdrive gear ratio. The E clutch is applied allowing torque to be transferred from the input shaft to the shell and sun gear No. 4 at a 1:1 ratio. The 2 inputs to the 4th planetary gearset cause the output shaft and planetary carrier No. 4 to rotate at a 0.85 ratio.

9th Gear

.jpg)

| Item | Description |

| 1 | B clutch |

| 2 | Sun gear No. 2 |

| 3 | Input shaft |

| 4 | Planetary carrier No. 2 |

| 5 | Ring gear No. 2 and sun gear No. 3 |

| 6 | C clutch |

| 7 | F clutch |

| 8 | Ring gear No. 4 |

| 9 | E clutch |

| 10 | Shell and sun gear No. 4 |

| 11 | Output shaft and planetary carrier No. 4 |

The B clutch is holding the sun gear No. 2 stationary. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 to rotate. The C clutch and F clutch are applied allowing torque to be transferred from the ring gear No. 2 to the ring gear No. 4 at a 0.63 overdrive gear ratio. The E clutch is applied allowing torque to be transferred from the input shaft to the shell and sun gear No. 4 at 1:1 ratio. The 2 inputs to the 4th planetary gearset cause the output shaft and planetary carrier No. 4 to rotate at a 0.69 ratio.

10th Gear

.jpg)

| Item | Description |

| 1 | B clutch |

| 2 | Sun gear No. 2 |

| 3 | Input shaft |

| 4 | Planetary carrier No. 2 |

| 5 | Ring gear No. 2 and sun gear No. 3 |

| 6 | C clutch |

| 7 | D clutch |

| 8 | F clutch |

| 9 | Planetary gearset No. 3 and planetary gearset No. 4 |

| 10 | Output shaft and planetary carrier No. 4 |

The B clutch is holding the sun gear No. 2 stationary. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 and sun gear No. 3 to rotate. The C clutch, D clutch, and the F clutch are applied to provide torque input from the ring gear No. 2 at an overdrive ratio of 0.56. This torque input effectively locks the 3rd and 4th planetary gearsets causing the output shaft and planetary carrier No. 4 to rotate at a 0.64 ratio.

Reverse

.jpg)

| Item | Description |

| 1 | B clutch |

| 2 | Sun gear No. 2 |

| 3 | Input shaft |

| 4 | Planetary carrier No. 2 |

| 5 | Ring gear No. 2 and sun gear No. 3 |

| 6 | A clutch |

| 7 | F clutch |

| 8 | D clutch |

| 9 | Planetary carrier No. 3 |

| 10 | Ring gear No. 3 |

| 11 | Shell and sun gear No. 4 |

| 12 | Output shaft and planetary carrier No. 4 |

The B clutch is applied to hold the sun gear No. 2 stationary. The input shaft turns the planetary carrier No. 2 and causes the ring gear No. 2 and the sun gear No. 3 to rotate at a 0.63 overdrive ratio. The A clutch, F clutch, and the D clutch are applied to hold the planetary carrier No. 3 stationary. The 2 inputs to the 3rd planetary gearset cause the ring gear No. 3 and the planetary carrier No. 4 to rotate at a 1.03 ratio in the reverse direction. The A clutch and F clutch are applied to hold the ring gear No. 4 stationary. The 2 inputs to the 4th planetary gearset cause the output shaft and planetary carrier No. 4 to rotate at a 4.85 reduction ratio in the reverse direction.

Component Description

Transmission Sensors

.jpg)

| Item | Description |

|---|---|

| 1 | Intermediate Speed A (ISSA) sensor |

| 2 | TSS sensor |

| 3 | Intermediate Speed B (ISSB) sensor |

| 4 | OSS sensor |

The PCM controls the electronic functions of this transmission. The PCM receives input signals from engine and transmission sensors and uses these inputs to control line pressure, shift time, TCC and shift solenoids.

| Item | Description |

| TFT Sensor | The TFT sensor is located in the transmission main control valve body. It is a temperature-sensitive device called a thermistor. The resistance value of the TFT sensor will vary with temperature change. The PCM monitors the voltage across the TFT sensor to determine the temperature of the transmission fluid. The PCM uses this initial signal to determine whether a cold start shift schedule is necessary. The cold start shift schedule allows delayed shifts when the transmission fluid is cold to help warm the transmission fluid. The PCM also inhibits TCC operation at low transmission fluid temperatures and adjusts line pressure for temperature. |

| TR Sensor | The TR sensor is composed of a dual set of TR sensors. The manual shifter engages and disengages Park and the shifter position is detected by reading TR sensors A and B. There is no manual valve, the PCM provides forward or reverse based on the dual TR sensor inputs. The 10R60 transmission uses a dual PWM output (at 125 Hz) TR sensors where: TR sensor A increases as the shifter is moved from Park to Sport and TR sensor B decreases as the shifter is moved from Park to Sport, together the sum of the two signals should add up to 100%. The 10R60 transmission mechanical shifter variant is range by wire with mechanical Park. The dual TR sensor's signals are used to determine customer selected range (P, R, N, D, S). PIDs, TR_A_DC and TR_B_DC may be utilized to monitor the TR sensor duty cycles. |

| TSS Sensor | The TSS sensor is a 2-wire Hall-effect type sensor that provides a turbine shaft speed signal to the PCM that changes in frequency as the magnetic trigger wheel part of the planetary carrier No. 2 varies in speed or direction. The turbine shaft speed information is compared to engine rpm to determine turbine shaft speed performance. Turbine shaft speed is also compared to output shaft speed to determine shift quality and clutch performance. The TSS sensor is mounted to the transmission case. |

| OSS Sensor | The OSS sensor is a 2-wire Hall-effect type sensor that provides a output shaft speed signal to the PCM that changes in frequency as the trigger wheel part of the output shaft and planetary carrier No. 4 varies in speed or direction. The output shaft speed is used for shift scheduling. Output shaft speed is also compared to turbine shaft speed to determine shift quality and clutch performance. The OSS sensor is mounted to the transmission case. |

| Intermediate Speed A (ISSA) Sensor | The intermediate speed sensor A (ISSA), is a 2-wire Hall-effect type sensor that provides an intermediate speed sensor A (ISSA) signal to the PCM that changes in frequency as the trigger wheel part of the No. 1 ring gear varies in speed or direction. The intermediate speed sensor A (ISSA) monitors clutch states for transmission fault detection and diagnostics. The intermediate speed sensor A (ISSA) is mounted to the transmission case. |

| Intermediate Speed B (ISSB) Sensor | The intermediate speed sensor B (ISSB), is a 2-wire Hall-effect type sensor that provides an intermediate speed sensor B (ISSB) signal to the PCM that changes in frequency as the trigger wheel part of the clutch and planetary container cylinder varies in speed or direction. The intermediate speed sensor B (ISSB) monitors clutch states for transmission fault detection and diagnostics. The intermediate speed sensor B (ISSB) is mounted to the transmission case. |

Shift Solenoids

.jpg)

| Item | Description |

| 1 | Armature/pin assembly |

| 2 | Part information |

The 10R60 utilizes six shift (A-F) solenoids that are linear force solenoids. Unlike previous shift solenoids they are mechanical in nature in that no transmission fluid passes through them. CIDASs use a armature/pin assembly that moves a control valve in the main control valve body to control and apply hydraulic fluid pressure. Each clutch (A-F) has a corresponding shift solenoid (A-F) that is directly proportional in that zero current equals zero pressure and maximum current equals maximum pressure. Since there is no pressure with zero current if the power is interrupted to the shift solenoids none of the clutch packs are able to engage.

Torque Converter Clutch (TCC) Proportional (VFS) and Line Pressure Control (LPC) Solenoid (Inversely-Proportional (VFS)

.jpg)

| Item | Description |

| 1 | Solenoid nozzle |

| 2 | Part information |

Torque Converter Clutch (TCC) Proportional (VFS)

Normally Low Solenoid

.jpg)

| Item | Description |

|---|---|

| 1 | Low current |

| 2 | High exhaust |

| 3 | SF circuit fluid (Supply) |

| 4 | Low pressure output |

| 5 | High current |

| 6 | Low exhaust |

| 7 | SF circuit fluid (Supply) |

| 8 | High pressure output |

The TCC solenoid is a variable force solenoid that varies hydraulic pressure by actuating a hydraulic valve. The TCC solenoid uses proportional operation. Normally low solenoids provide hydraulic pressure proportional to supplied current. A normally low solenoid will output very low pressure with low (50 mA) or no current, while it will supply high pressure with high current (850 mA).

Line Pressure Control (LPC) Solenoid (Inversely-Proportional (VFS)

Normally High Solenoid

.jpg)

| Item | Description |

|---|---|

| 1 | Low current |

| 2 | Low exhaust |

| 3 | SF circuit fluid (Supply) |

| 4 | High pressure output |

| 5 | High current |

| 6 | High exhaust |

| 7 | SF circuit fluid (Supply) |

| 8 | Low pressure output |

The LPC solenoid is a variable force solenoid that varies hydraulic pressure by actuating a hydraulic valve. The LPC solenoid uses inversely proportional operation. Normally high solenoids provide full output of pressure with low or no current (50 mA) and very low pressure with high current (850 mA).

Transmission External Sealing

The front support cover and seal assembly has a bonded rubber seal around the outside that seals to the front support housing. A removable rubber seal on the inside of the front support cover seals the area around the front support cover bolt. A torque converter hub seal is held into the front support cover with a snap ring.

The front support assembly uses a large rubber seal that seals the support housing to the transmission case.

The transmission fluid cooler tubes use 2 rubber seals with plastic backing rings to seal the tubes to the transmission case.

On the left side of the transmission case, there is a line pressure tap plug.

The manual control shaft has a lip seal that is pressed into the transmission case.

The transmission fluid pan has a reusable gasket.

The output shaft uses a lip-type seal that seals to the transmission case and output shaft nut. The output shaft nut has a bonded rubber O-ring on the inside that seals to the shaft threads.

The large transmission case housing plug provides access to the park pawl shaft and has an O-ring seal.

The park pawl actuator sleeve has 2 O-ring seals that seal to the transmission case.

A plug seals the E clutch fluid passage in the rear of the transmission case.

The internal wiring harness bulkhead connector has 2 O-ring seals for the transmission case bore.

The transmission fluid level indicator plug uses an O-ring seal.

The transmission vent tube is pressed into the transmission case.

.jpg)

.jpg)

| Item | Description |

| 1 | Front support cover and seal assembly |

| 2 | Seal part of front support cover and seal assembly |

| 3 | Front support-to-case seal |

| 4 | Transmission fluid cooler tube seals (2 required) |

| 5 | Line pressure tap plug |

| 6 | Manual control shaft seal |

| 7 | Transmission fluid pan gasket |

| 8 | Output shaft nut |

| 9 | Output shaft seal |

| 10 | Park pawl actuator rod sleeve seals (2 required) |

| 11 | Park pawl shaft plug |

| 12 | Transmission case plug |

| 13 | Internal wiring harness bulkhead connector O-rings |

| 14 | Transmission fluid level indicator plug O-ring |

| 15 | Transmission vent tube |

Vehicle Shift System

.jpg)

| Item | Description |

| 1 | Park lock pawl valve |

| 2 | Park lock pawl solenoid |

| 3 | TR sensor |

| 4 | Park return spring |

| 5 | Park pawl actuator rod |

| 6 | Park pawl |

| 7 | Output shaft and planetary carrier |

Park by Wire

- Uses a GSM with a rotary gear shift knob in place of a mechanical shifter for selecting P, R, N, D, M.

-

The transmission hydraulic controls are modified

using a park lock pawl valve connected to the park rod which unlocks and

locks the park pawl from the carrier.

- Uses clutch B and D hydraulic pressure to push the system out of Park.

- Once out of Park, clutches A, B, C, D or F can continue to hold the system out of Park.

- A park lock pawl solenoid allows the system to remain out of Park when the engine is not running.

- The dual TR sensors indicate the state of the Park system and are not used to determine customer selected range, which is now provided by the GSM.

- A mechanical P override has been provided for in-plant use and towing. This consists of a cable running from the console to the transmission, a bracket and lever assembly mounted to the side of the transmission and a lever on the side of the transmission. In the override position the park lock pawl valve is held in the applied position to keep the park pawl unlocked from the carrier.

Drive Modes

The Selectable Drive Mode system customizes vehicle handling and performance for most driving conditions by utilizing sophisticated electronic vehicle systems. These systems optimize steering, handling and engine performance and transmission shifting to provide a robust driving experience. This provides a single location to control multiple systems performance settings.

Changing the drive mode automatically changes the functionality of the following systems:

- Electronically power-assisted steering system adjusts steering effort and feel based on the mode you select.

- Electronic stability control and traction control maintain your vehicle control in adverse conditions or high performance driving.

- Electronic throttle control enhances the powertrain response to your inputs.

- Driveline settings are optimized with shift schedules tuned to each drive mode.

The drive modes are ready to assist the driver in vehicle control for both on-road and off-road conditions. The modes are as follows:

On-Road Drive Modes

- Normal Mode: A perfect balance of excitement, comfort and convenience for everyday driving.

- Sport Mode: For aggressive on-road driving, sport mode increases throttle response, provides a sportier steering feel, along with quicker shifting. The transmission also holds gears longer, helping your vehicle accelerate faster when shifting gears.

- Tow Haul: For improved transmission operation when towing a trailer or a heavy load, tow haul mode moves upshifts to higher engine speeds to reduce the frequency of transmission shifting. This mode also provides engine braking in all forward gears, which slows the vehicle and assists in controlling the vehicle when descending a grade. The amount of downshift braking provided varies based on the amount the brake pedal is pressed.

Off-Road Drive Modes

- Snow/Wet (4X2) or Grass/ Gravel/Snow (AWD): For firm surfaces covered with loose or slippery material such as packed snow, ice, water, grass or a thin layer of gravel or sand.

- Sand Mode: For soft dry sand or deep gravel.

- Mud/Rut: For muddy, rutted, soft or uneven terrain.

For information on driving mode diagnosis,

Description and Operation - Transmission Description

Description and Operation - Transmission Description

Transmission Assembly

Item

Part Number

Description

1

79027902

Torque converter

2

W714629W714629

Transmission fluid pan stud bolts (6 required)

3

W500215W500215

Transmission fluid pan bolts (12 required)

4

7A1947A194

Transmission fluid pan

5

7A1917A191

Transmission fluid pan gasket

6

7E3897E389

Transmission fluid level indicator and plug assembly

7

W708500W708500

Transmission fluid auxiliary pump tube bolt (model dependent)

8

7A2097A209

Transmission fluid auxiliary pump tube (model dependent)

9

W718548W718548

Transmission fluid auxiliary pump bolts (3 required) (model dependent)

10

7P0867P086

Transmission fluid auxiliary pump (model dependent)

11

7J1357J135

Transmission fluid auxiliary pump tube seal (model dependent)

12

W700123W700123

Transmission fluid filter bolt (71 mm length)

13

W500214W500214

Transmission fluid filter bolt (20 mm length)

14

7G1867G186

Transmission fluid filter

15

W708500W708500

Main control-to-transmission case bolts (68 mm length) (8 required)

16

7A1007A100

Main control assembly

17

7N2657N265

Main control-to-transmission fluid pump seal

18

7M1837M183

Intermediate Speed A (ISSA) sensor

19

7M1017M101

Turbine Shaft Speed (TSS) sensor

20

7H1037H103

Intermediate Speed B (ISSB) sensor

21

7H1037H103

Output Shaft Speed (OSS) sensor

22

W500213W500213

Transmission internal wiring harness bolts (2 required)

23

7G2767G276

Transmission internal wiring harness

24

W500215W500215

Transmission fluid pump bolts (4 required)

25

7A1037A103

Transmission fluid pump

26

7Z3027Z302

Transmission fluid pump seal

27

66586658

Transmission fluid pump driven gear outer cover

28

W718158W718158

Transmission fluid pump retaining ring

29

7A0807A080

Transmission fluid pump driven gear

30

W504755W504755

Transmission fluid pump driven gear inner cover bolts (2 required)

31

66586658

Transmission fluid pump driven gear inner cover

32

7K4407K440

Output shaft flange nut (RWD only)

33

7A0217A021

Output shaft flange (RWD only)

34

7N1357N135

Anti-ting washer (RWD only)

35

7G1007G100

Manual control shaft-to-Transmission Range (TR) sensor roll pin

36

W712713W712713-S442-S442

Park override lever nut

37

7J1677J167

Park override lever

38

7C4937C493

Manual control shaft

39

7H5577H557

Transmission Range (TR) sensor

40

7L2527L252

Park return spring

41

7D4107D410

Park pawl actuator rod

42

W716607W716607

Transmission Range (TR) sensor detent spring bolt

43

7E3327E332

Transmission Range (TR) sensor detent spring

44

7N1347N134

Front support assembly bolts (12 required)

45

7G0337G033

Front support assembly

46

7M1577M157-C-C

B clutch (overdrive) snap ring

47

7C5767C576

B clutch (overdrive) pressure plate

48

7B4427B442-A-A

B clutch (overdrive) steel plates (quantity model dependent)

49

7B1647B164

B clutch (overdrive) friction plates (quantity model dependent)

50

7J4027J402

B clutch (overdrive) separating springs (quantity model dependent)

51

7B4427B442-B-B

B clutch (overdrive) apply plate

52

7G2067G206

One-Way Clutch (OWC)

53

7G4187G418

B clutch (overdrive) piston

54

7N1697N169

A clutch (intermediate) piston return spring snap ring

55

7G2977G297

A clutch (intermediate) piston return spring

56

7J0157J015

A clutch (intermediate) piston

57

7F2257F225

A clutch (intermediate) piston inner seal

58

7F2247F224

A clutch (intermediate) piston outer seal

59

7B0317B031

Front support-to-case seal

60

7M1577M157-J-J

Torque converter hub seal snap ring

61

7A2487A248

Torque converter hub seal

62

W500204W500204

Front support cover and seal assembly bolt

63

7M1577M157

Front support cover and seal assembly snap ring

64

75707570

Front support cover and seal assembly

65

7F0737F073

Transmission fluid pump drive gear

66

66516651

Transmission fluid pump idler gear

67

7Z4267Z426

Transmission fluid pump idler gear bearing

68

7G0907G090

Stator support seal

69

—

Clutch and planetary assembly

70

7P0807P080

A clutch (intermediate) wave spring

71

7A4067A406

A clutch (intermediate) apply plate (select fit)

72

7F2197F219

A clutch (intermediate) friction plates (quantity model dependent)

73

7F2207F220

A clutch (intermediate) steel plates (quantity model dependent)

74

7G1597G159

A clutch (intermediate) separating springs (quantity model dependent)

75

7B4377B437

A clutch (intermediate) pressure plate

76

7J3007J300

Selective shim

77

7H0327H032

Thrust bearing (T3)

78

7M1527M152-A-A

Thrust bearing (T9)

79

7A0497A049

Output shaft and planetary carrier No...

Description and Operation - A Clutch

Description and Operation - A Clutch

Overview

Item

Description

1

SSA

2

A clutch control valve

3

A clutch latch valve

4

A clutch apply circuit

5

A clutch piston

6

A clutch assembly

7

Ring gear No...

Other information:

Lincoln Aviator 2020-2026 Owners Manual: Rear Passenger Climate Controls

Use the rear passenger touchscreen to select the following: Touch the climate button on the feature bar to access the rear passenger climate control screen. Rear Passenger Climate Control Screen Selecting a Row Touch 2nd Row to control the second row climate...

Lincoln Aviator 2020-2026 Service Manual: Diagnosis and Testing - F Clutch

Symptom Chart F Clutch For F clutch operation, REFER to: F Clutch (307-01A Automatic Transmission - 10-Speed Automatic Transmission – 10R60, Description and Operation). F Clutch Condition Possible Sources Action F clutch does not apply SSF is mechanically stuck OFF INSTALL a new solenoid...

Categories

- Manuals Home

- Lincoln Aviator Owners Manual

- Lincoln Aviator Service Manual

- Opening and Closing the Hood

- Configuring The Head Up Display

- Body and Paint

- New on site

- Most important about car

Fastening the Seatbelts

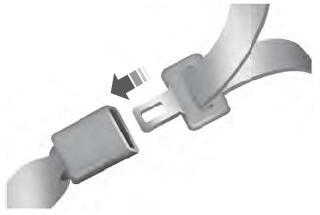

The front outboard and rear safety restraints in the vehicle are combination lap and shoulder belts.

Insert the belt tongue into the proper buckle (the buckle closest to the direction the tongue is coming from) until you hear a snap and feel it latch. Make sure that you securely fasten the tongue in the buckle.

.jpg)